Rebound O&P

Updated 3:55 PM CST, Mon December 9, 2024

Published Under: 3D printing Cranial Helmets Orthotics Prosthetics

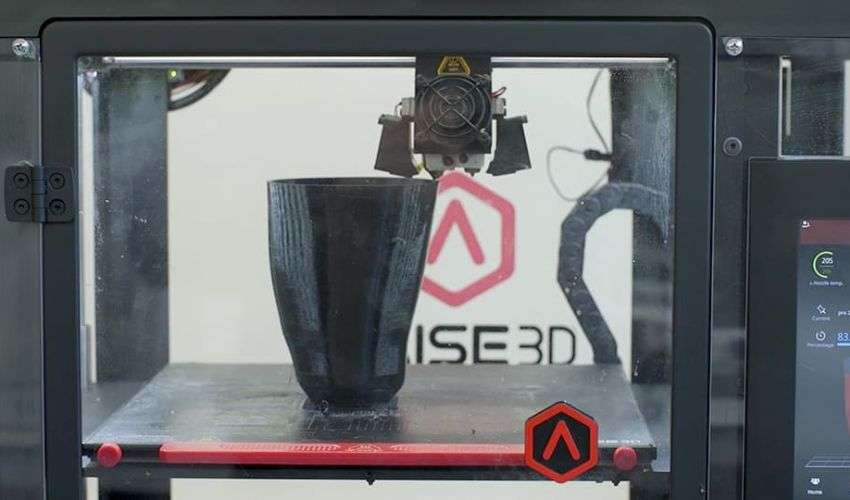

The advent of 3D printing technology has brought about transformative changes across various industries, and the field of orthotics and prosthetics is no exception. This innovative manufacturing process is reshaping how devices are designed, produced, and fitted, making them more accessible, customizable, and effective. In this blog, we’ll explore how 3D printing is revolutionizing the orthotic and prosthetic landscape, enhancing patient outcomes, and changing the way healthcare professionals approach treatment.

1. Customization and Personalization

One of the most significant advantages of 3D printing in orthotics and prosthetics is its ability to create highly customized devices tailored to individual needs. Traditional manufacturing methods often require extensive modifications to achieve the right fit, which can be time-consuming and costly.

With 3D printing, practitioners can quickly create models based on a patient's unique anatomy, leading to a better fit and enhanced comfort. Advanced scanning technologies capture detailed measurements of a patient's body, allowing for precise designs that accommodate specific conditions, preferences, and lifestyle requirements.

2. Speed of Production

3D printing significantly reduces the time required to produce orthotic and prosthetic devices. Traditional methods can take weeks to design, fabricate, and fit a device, often resulting in delays in patient care.

In contrast, 3D printing can shorten this timeline dramatically. Once the design is complete, the printing process can take just a few hours or days, allowing patients to receive their devices much faster. This rapid production capability is especially beneficial in acute care situations or for growing children who need frequent adjustments.

3. Cost-Effectiveness

The cost of orthotic and prosthetic devices has long been a barrier for many patients. Traditional manufacturing processes involve significant labor and material costs, which can make these devices prohibitively expensive.

3D printing can help lower costs by streamlining the manufacturing process and reducing waste. The ability to produce devices on demand minimizes inventory costs and allows for more efficient use of materials. As 3D printing technology continues to evolve, we can expect even greater reductions in costs, making these vital devices more accessible to a wider range of patients.

4. Enhanced Design Flexibility

3D printing opens up new avenues for innovative designs that were previously difficult or impossible to achieve with traditional manufacturing methods. The ability to create complex geometries allows for more functional and aesthetically pleasing devices.

For example, prosthetic limbs can incorporate lightweight lattice structures that provide strength without adding bulk. Similarly, orthotic braces can be designed with ventilation and flexibility to enhance comfort during use. This design freedom enables healthcare professionals to create devices that not only meet functional requirements but also reflect the personal style and preferences of the user.

5. Improved Patient Outcomes

The combination of customization, speed, and cost-effectiveness directly contributes to better patient outcomes. With 3D-printed orthotics and prosthetics, patients often experience improved comfort, better fit, and enhanced functionality.

Additionally, the rapid turnaround time allows for quicker adjustments and iterations, ensuring that devices are continually optimized for performance. This responsiveness can lead to increased patient satisfaction and better adherence to prescribed therapies, ultimately supporting long-term mobility and quality of life.

6. Educational Opportunities

3D printing technology also offers valuable educational opportunities within the orthotic and prosthetic fields. Students and practitioners can use 3D printing to create models for training purposes, helping them understand anatomy and device mechanics in a hands-on manner.

Furthermore, collaborative projects that involve patients in the design process can foster a sense of ownership and empowerment, encouraging active participation in their treatment journey.

Conclusion

The integration of 3D printing into the orthotic and prosthetic field is nothing short of revolutionary. By enabling customization, speeding up production, reducing costs, and enhancing design flexibility, this technology is improving patient outcomes and reshaping the future of mobility solutions. As 3D printing continues to advance, we can expect even more innovative applications that will further enhance the lives of individuals relying on orthotic and prosthetic devices. The future is bright, and with it comes the promise of greater accessibility, improved designs, and better quality of life for those who need it most.

Comments